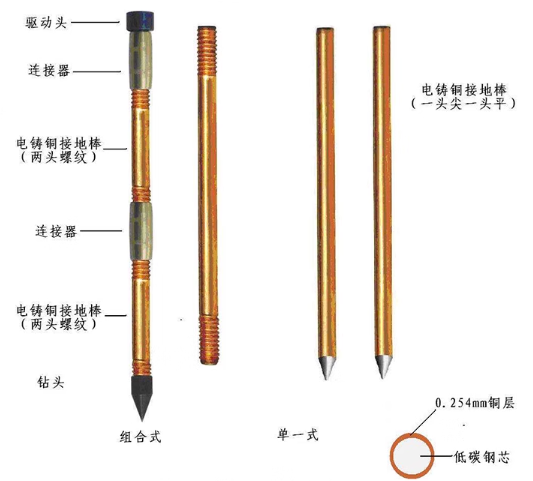

OML-TBG copper-clad steel grounding rod, copper-clad grounding electrode, ion grounding electrode, lightning protection grounding pile, vertical grounding electrode for lightning protection grounding network

Product Description:

Omrdon (omrdon) copper-clad steel grounding rod, using 600T hydraulic cold-drawing composite technology, in the high-strength A3 steel core surface, composite layer of more than 0.25 thickness of copper. On the one hand, the use of copper's excellent electrical conductivity, acid and alkali resistance, greatly increasing the conductive capacity and service life; at the same time, the use of A3 steel core strength, easy to hit the hard soil, so that the construction difficulty is greatly reduced. The traditional grounding materials, flat iron or flat steel. Its biggest drawback is that it is easy to corrode. Limited service life, generally two to three years, has been all corroded, thus losing the role of grounding. This situation, resulting in a large amount of waste of manpower and material resources.

Functional Features::

- 600T hydraulic cold drawing molding, good bonding, not easy to delamination.

- Wrapped in 99% pure copper for superior conductivity and corrosion resistance.

- Uniform copper layer, smooth surface, no defects, good protection for the steel core.

- The steel core is made of A3 steel, which has high strength and large deformation without brittle crack.

- Both ends of the car wire or roller wire, easy to connect, can be freely extended to more than 10m.

typical application::

- Communication base station lightning protection and grounding

- Computer room lightning protection and grounding

- Petrochemical plant lightning protection and grounding

- Lightning protection and grounding for power plants

Technical Parameters::

| model number | Dimensional parameters |

| OML-TBG14/****(L) | Φ14, T=0.25, L=1.5/2/2.5/3 |

| OML-TBG16/**** | Φ16, T=0.25, L=1.5/2/2.5/3 |

| OML-TBG18/**** | Φ18, T=0.25, L=1.5/2/2.5/3 |

| OML-TBG20/**** | Φ20, T=0.25, L=1.5/2/2.5/3 |

| OML-TBG25/**** | Φ25, T=0.25, L=1.5/2/2.5/3 |

T: indicates the thickness of the copper layer, unit mm; L: indicates the length, unit m.

Product Installation Diagram::

Installation Instructions:

1, with a drilling rig to drill a well with a diameter of about 10cm, according to the use of different models, the depth of 1.5~3.5 meters (30~50cm greater than the length of the ion grounding rod).

2、Mix the additional ion dispersant with the long-lasting drag-reducing agent and mix it into a paste in the well, and fill it for the first time at a depth of about 30cm.

3, the use of not less than 10mm multi-stranded copper core wire or copper row and ion grounding rod cover end terminals connected, and will cover the end of the ion exchange hole on the tape torn off, placed vertically in the well on the filler.

4. Add the remaining filler to the well in several layers and compact in layers using tools.

5, the grounding wire through the well cover (precast concrete) holes, lead to the grounding busbar or grounding terminal box, and cover the well cover, make a good sign, in order to facilitate maintenance.

If more than one construction, all the roots with copper tape or other metal conductor connected, will lead one to the grounding test point test, meet the requirements, backfill, restore vegetation, complete the construction. (See grounding rod grounding principle diagram)

Omrdon Technology

Omrdon Technology